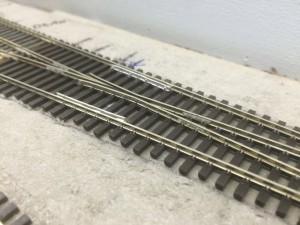

I spent a good portion of my modeling time this summer modifying and super-detailing three Peco turnouts. I replaced the frogs with Details West #8 Manganese frogs, filed new guard rails, added fish plates and rail braces. The process was fairly simple, but time consuming.

Unfortunately, my gorgeous manganese frogs don’t work. The Details West frogs appear to conform to NMRA S 3.2 Trackwork Standard Scales, the depth of the flanges are .025″, but the NMRA S 4.2 Wheels Standard Scales allow for a wheel depth of .028″. It appears that wheels are allowed to be deeper than flangeways.

So I have to rip these turnouts out. I’ll replace them with Peco Electrofrog turnouts. I’m super-detailing each one with fish plates, frog bolts and point bolts. The first one has been installed.

5,114

It’s almost a shame that you couldn’t get small castings that could be glued onto the sides of the stock Peco frog to bulk it up to the manganese frog’s shape. I’m possibly oversimplifying things but looking at the two I was wondering if the shape of the manganese frog could be built up instead of replacing the frog casting? Maybe even merging in part of the original Details West casting?

Chris

Actually Proto:87 can work just as well as HO, even on not very well laid track, if you follow the guidelines and typically use simple proper suspension.

Obviously seeing is believing, so check out the March 2015 You tube clips I just put up showing an 8 car train of Walthers’ Amfleets running around a 1 scale mile loop indefinitely at a scale 120 mph.

https://www.youtube.com/watch?v=svTDe2u797Y

And to show that this isn’t “on the edge”, here is the same train, running 120 mph backwards just as happily.

https://www.youtube.com/watch?v=hsgcH9800_8

For questions or more explanations than fit in this small space, contact me at the Stores website email.

Andy

Great to see you back at it. I was also scratchbuilding turnouts and feel the same. I´m building a switching layout and will use Atlas code 83 turnouts, max 5-6 turnouts. When scratchbuilding turnouts the most difficult part is installing the points and the throwbar and to get it works ok. Need to grow my skills and maybe in the future I´ll swap the Atlas turnouts with custom built turnouts.

Like your posts and layouts updates, keep them coming.

Details West Frogs, if they are still made, should have deep enough flange ways, but do have 0.040″ NMRA HO-Fine flange way width rather than the regular NMRA HO 0.050″ width. That may be causing then issue you found.

I had already tried this too – with the same result. So I have a very pretty looking turnout which makes the rolling stock bump, or butt ugly turnouts that work.

Not that impressive, considering it’s the 21st century and every other element of model railroading is awesome, but track is still in the stone age.

Nice to see you back at it, Greg! For what my opinion is worth, I think you made the most practical choice regarding switches.

Shoot me an e-mail sometime (Paul.Schmidt@BNSF.com) or call my cell 206-396-0337. I’m the Seattle signal electronic technician. Love to get together and talk trains with you!

Paul

Hello Greg,

Great to see back modelling again. Its a shame that you cant use those nice frogs, but at least with Peco you wont need to worry about them and can concentrate on modelling other things.

It will be good to have someone else modelling the Seattle area.

Welcome back

Robin