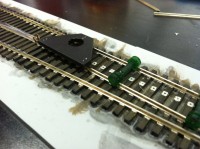

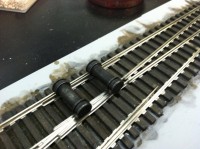

February has been a hard month and my second turnout project has been stalled by parts delays, illness, a death, and a vacation. Patrick and I layed out the ties earlier this month and were waiting for a new frog from Andy at Proto:87 Stores. I had Andy build a new frog because I screwed up the last one. I glued in most of the tie plates before I left for vacation. While I was on vacation some new track gauges arrived from DDWheelwrights and Railway Engineering. Having a set of track gauges provided me the motivation to finish the tie paltes and

Essons Learned

- Gluing tie plates is a pain in the ass. I tried using a syringe to squirt CA glue onto the ties, but the syringe got blocked up rather quickly and became unusable after a day. I tried using a toothpick to dab a small amount on the ties, but the dabs were frequently too big and would spread to the jig. Too little glue and the tie plates fall off. I found myself constantly being set back by tie plates that came loose. I don’t know if this is a process I’m willing to continue with this method of turnout building.

- The Proto:87 Stores throwbar is very difficult to install correctly. I ordered extra, because I had trouble before and I had to use the extras. I finally got it to work long enough to take a couple of photos, then it fell apart. In the end, I soldered a PCB tie to the points.

- I needed to file the inside tips of the points so the wheels won’t trip on them.

2,361

What level CA are you using? A drop of the thick CA shouldn’t run.

Hi Mikey,

I’ve tried thick and extra thick. The problem with a drop is it’s too big and gets pushed out under the jig when I press a tie plate into it, or the drop is too big it contacts a side of the jig causing it to stick to the tie. I think I need a steadier hand and a better dropper.

Greg

Got a magnifying glass? 😉 That’s why I would have a hard time going back to HO 🙂

The solders on throw bar actually works great, it’s the glue down stainless steel hooks that are giving me the problems. I actually had a CA applicator that was like the eye of a needle, it worked alright, but still hard to place the CA drop in the cutout holes for the tie plates. I need bigger scale track or smaller scale fingers 😉

Have you tried using the eye of a needle to spread the CA on the tie plates? The syringe sounds like it’s to uncontrolled? Try dipping the end of a old needle in a puddle of CA on a piece of scrap styrene.

I’m wondering if your soldering iron isn’t getting the points hot enough to melt the solder when you try to solder the throw bar? Or something isn’t clean to allow the solder to flow where you placed flux?